PD Series - Diagnostic Hydraulic Quick Couplings (ISO 15171-1)

Double Shut-Off Quick Couplings

Interchanges with

Parker PD series, Aeroquip FD90 series, Tomco DK, Faster DF Series

Applications

PD Series couplings provide easy connection for mechanical gauges or specialized diagnostic equipment.

Typically, PD nipples are permanently mounted in the system at threaded test ports, in rigid tubing or in hose assemblies. PD couplers are attached to test instruments. Couplers align to the mating nipples without threading. This allows gauges, transducers and other test equipment to be snapped into place without difficulty.

Features

■ Flush-face poppet valves minimize air inclusion and spillage, provide easy-to-clean surfaces, and help to prevent contamination.

■ Grip-tight knurled sleeves help to make connecting and disconnecting easy, even while wearing gloves.

■ The safety sleeve locking design prevents accidental disconnection, Push-to-connect design allows one-hand-operation.

■ Nipples are machined from high tensile steel for strength to withstand 6000 PSI continuous operating pressure.

■ PD nipples are designed to meet or exceed SAE J1502 and ISO 15171-1 design and performance specifications.

■ End connections include pipe, O-ring, metric thread, bulkhead, 37° Flare, ORFS and so on.

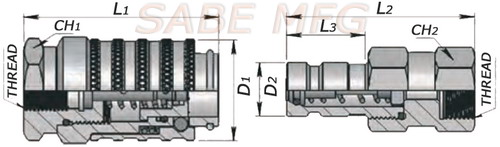

| Part No. | Body Size | Thread | L1 | L2 | L3 | D1 | D2 | CH1 | CH2 |

| PD | 1/8" | 1/8" | 42.5 | 37.5 | 17.8 | 24.5 | 12.6 | 21 | 17 |

| PD | 1/8" | 1/4" | 54 | 41.5 | 17.8 | 24.5 | 12.6 | 21 | 19 |

Standard Material: Steel

Specification

| Body Size (inch) | 1/8" |

| Rated Pressure (PSI) | 6000 |

| Vacuum Data (inches Hg) | 27.5 |

| Rated Flow (GPM) | 0.8 |

| Temperature Range | -20°C to +80°C |

| Seal Standard | NBR(Nitrile) |

FPM(Viton®) seal is available, Please indicate if you need