Location: Home > Hydraulic Quick Couplings > MK - Nitto Mold Cupla Quick Disconnects

|

|

|

MK Series |

MK Series - Japanese/Nitto Style Mold Quick Disconnects

Single Shut-Off General Purpose And Mold Coolant Port Coupling

Industry Standard & Interchanges With

Nitto Mold Cupla Series

Features

- Designed for quick replacement for die and mold. Valved coupler and non-valved nipple.

- Nipples are designed to be recessed below mold surfaces to provide more efficient storage of molds and prevent damage to the nipple.

- Various sizes and configurations to suit a wide variety of mold applications, including straight, elbow with male, female thread, standard hose barb which Enables quick mold coolant hose connection/disconnection for easy installation.

- Couplers and nipples are made of corrosion resistant brass, and valved couplers has a Fluorocarbon O-ring on poppet and Silicone interface seal as standard for use with water glycol type fluids commonly used in heat transfer systems.

- Long sleeve socket facilitates connection/disconnection with plug embedded in mold.

Applications

KM Series couplings are specifically designed for connecting coolant lines to molds and dies, on injection molding machinery in the plastics and die casting industries. KM Series couplings significantly reduce machine downtime by providing fast and easy connection of coolant lines during mold changes. Space saving design for molds with closely spaced coolant ports. couplers are available with or without valves in the female half. Non-valved couplers provide maximum flow for efficient cooling. Valved couplers shut off when disconnected.

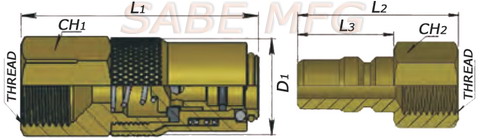

| Nipple P/N | Coupler P/N | Thread | L1 | L2 | L3 | CH1 | CH2 | D1 |

| MK2-2PF | MK2-2SF | 1/4 | 46.5 | 30.5 | 15 | 17 | 17 | 21 |

Standard Thread Rc Female Thread, other thread available for custom order

Standard Material: Brass

Specification

| Rated Pressure (Mpa) | 1.0 | ||

| Rated Flow (L/Min) | 15 | ||

| Seal Standard | Temperature Range | ||

| Silicone seal | -20°C ~ +80°C | ||

| FPM(Viton®) seal | -20°C ~ +180°C | ||