TL Series - Screw Threaded Locking / High Pressure Standard Coupling

Double Shut-Off Quick Couplings

Interchanges with:

Parker 3000, Safeway S30, Hansen WA 56000/HP 3, Faster PVVM, Tuthill W-6000, Enerpac C-604, Stucchi IV, Snap-Tite 76, DNP PVM, Dixon T Series

Features

■ Machined from solid steel barstock for durability. Rated working pressure of 10,000 psi in all sizes.

■ The TL Series employs a threaded sleeve locking mechanism as coupling halves, mates with matching male threads on the nipple.

■ Hard,chrome alloy balls are used for valving. They a spring loaded for positive seating of the valve.

■ Poppet style valving with double shut-off. Captive poppet seal provides a durable, guaranteed leak-free seal.

■ The valve provides a metal-to-metal seal between the ball and a cone seat.

■ The Interface seal is polyurethane which resists high pressure extrusion.

■ A threaded valve retainer provides a valves stop that assures positive valve alignment.

Applications

TL Series couplings with their threaded union locking system is designed for extreme high pressure applications such as portable hydraulic rams, wire pullers, and frame straightening equipment, etc.

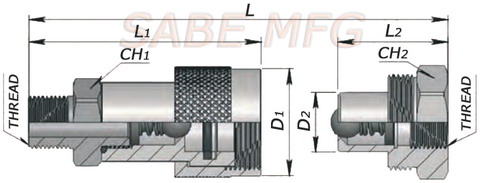

| Part No. | ISO DN | Body Size | Thread | L | L1 | L2 | D1 | D2 | CH1 | CH2 |

| TL06 | 6.3 | 1/4" | 1/4" | 78 | 63 | 34 | 30 | 15.8 | 21 | 27 |

| TL10 | 10 | 3/8" | 3/8" | 98 | 84 | 39 | 36 | 19 | 25 | 32 |

Standard Thread: BSPP & NPT Female Thread, other thread available for custom order

Standard Material: Steel

Poppet Valves & Ball Valves Available

Specification

| Body Size (inch) | 1/4" | 3/8" |

| Rated Pressure(PSI) | 10000 | 10000 |

| Rated Flow(GPM) | 3 | 6 |

| Temperature Range | -20°Cto+80°C | |

| Seal Standard | NBR(Nitrile) | |

FPM(Viton®) seal is available, Please indicate if you need