GLP Series - German Low Pressure Hydraulic Quick Action Couplers

Double Shut-Off Quick Couplings

Non-Valve Optional For Nipple

Interchanges with

Walther LP series

Applications

GLP Series couplings are sued in Automotive industry, Machine and systems engineering, Chemical and pharmaceutical industry, Steel industry, Offshore technology, Transportation technology, Medical technology, Aerospace and aviation and Defence technology. (refer to and depend on the performance of this series)

Features

■ Heavy duty design as standard. Machined from high grade carbon steel for durability.

■ Triangle poppet valve. Nipple also deisnged without vavle.

■ Hardening treatment for specific stressed area like nipple.

■ Media: water, compressed air, diverse fluids, fuel, lubricating greases / oils, technical gases.

■ Squirt-free, locking aid, ring grips for larger nominal bores.

■ Modular end construction to support broad choice of end configurations such as optional 24° cone (Bulkhead) - DIN 2353, Male BSPP - DIN 3852-B with DIN 60° cone.

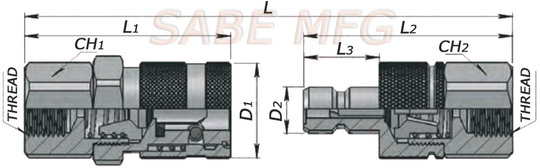

| Part No. | Body Size DN | Thread | L | L1 | L2 | L3 | D1 | D2 | CH1.2 |

| GLP06 | 06 | 1/4 | 93 | 58 | 55 | 20 | 25 | 10.9 | 19 |

| GLP07 | 07 | 3/8 | 109.7 | 68 | 65 | 23.3 | 30 | 15.9 | 24 |

| GLP12 | 12 | 1/2 | 132.5 | 82 | 80 | 29.5 | 40 | 20.9 | 32 |

| GLP19 | 19 | 3/4 | 163.5 | 100 | 96 | 32.5 | 54 | - | 46 |

Standard Thread: BSPP & Metric Female Thread, other thread available for custom order

Standard Material: Steel

Specification

| Body Size (DN) | 06 | 07 | 12 | 19 |

| Rated Pressure (Mpa) | 15 | 15 | 15 | 15 |

| Rated Flow (L/Min) | 15 | 25 | 50 | 120 |

| Temperature Range | -20°C to +80°C | |||

| Seal Standard | NBR(Nitrile) | |||

FPM(Viton®) seal is available, Please indicate if you need